Improve customer service and reduce costs for medical device logistics.

RFID-enabled track & trace for efficient shipment and installation.

Faster medical device deployment with improved logistics efficiency.

A machine builder can get medical devices shipped and installed faster with RFID.

Challenge: A Major Logistics Efficiency Increase

A machine builder aimed to increase customer service levels while reducing costs. The company sought a partner to implement a solution that would support fast, complete shipments of medical devices and enhance installation speed in hospitals.

Solution: Shipment and Installation Track & Trace with Custom RFID Labels

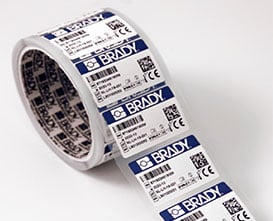

Together with a partner, Brady presented a complete and efficient logistics solution driven by RFID. Brady provided RFID labels, print-and-program printers, while the partner offered custom software and scanners.

Brady selected its L-2588-26B RFID label and customized the size to an A5 format. A suitable RFID inlay with up to 10 meters read range was integrated, and each label was equipped with an acrylic adhesive. These labels can be programmed and printed by the customer using RFID print-and-program printers provided by Brady. Labels are added to every medical device component package when it is picked in the machine builder’s warehouse. Because of this, line of sight is no longer required to identify every component, and identification becomes possible from a greater distance.

RFID scanner gates check each component package against cargo lists in the customer’s ERP system. Incorrect components are flagged, missing pieces are highlighted, and complete shipments are confirmed with ease.

Upon arrival at the end-user location or within the logistical chain, cargo completeness is quickly verified by walking around the truck with an RFID scanner. Efficient unloading is facilitated as the RFID labels and custom software guide where contents need to be set up. Installers can organize and unload components effectively.

Using the software, RFID labels guide installers in the correct installation order. Proximity alerts help locate even the smallest component packages, enabling fast and accurate setup of new medical devices in hospitals.

Results: Medical Devices Operational Faster with Custom RFID Labels

Medical devices can now be made operational in hospitals at greater speed with RFID. Efficiency gains begin with ensuring complete shipments of medical device component packages to any hospital worldwide. Installers no longer need to visually identify hundreds of component packages. Instead, they can rely on proximity detection powered by custom software and RFID scanners, along with on-site printable RFID labels.