Labels by Sign and Label Printer

Labels by Specialty Printers and Applicators

- Aggressive Adhesive Labels

- Chemical Resistant Labels

- Glow in the Dark Labels

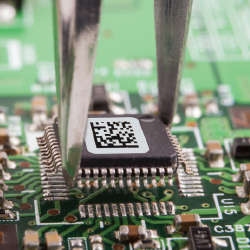

- Harsh Environment Labels

- Heat Resistant Labels

- Heat Shrink Sleeves

- Laser Markable Labels

- Low Temperature Labels

- Magnetic Labels

- Metal Detectable Labels

- Metallic Labels

- Outdoor Durable Labels

- Permanent Adhesive Labels

- Reflective Labels

- Removable Labels

- Repositionable Labels

- Static Dissipative Labels

- Tamper Evident Labels

- Temperature Indicating Labels

- Washdown Resistant Labels

- Water Dissolvable Labels

- Water Indicating Labels