Efficient LOTO Tool Distribution With Shadow Boards

Case Study

Enhance safety culture with better Lockout/Tagout visibility and efficiency.

Custom Lockout/Tagout shadow boards for tool visibility and organization.

Improved safety reminders and efficient Lockout/Tagout tool management.

A large soy processor uses Lockout/Tagout shadow boards to visualise a strong safety culture in the workplace.

Challenge: Take a strong safety culture to the next step

A large soy processor had already fostered a strong safety culture in its main production facility. To maintain and further strengthen this culture, the company was looking for solutions that help keep employee safety top of mind in the workplace.

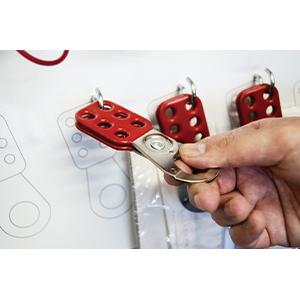

Part of the soy processor’s strong safety culture is supported by Lockout/Tagout, which completely isolates machinery from its energy supply while maintenance interventions are ongoing. This is achieved by following step-by-step procedures to deenergise specific machines, and by enabling maintenance specialists to temporarily lock this isolated machine state in place with their personal safety padlocks.

The company now wanted Lockout/Tagout to play a bigger role in its overall workplace safety culture.

Solution: Custom Lockout/Tagout Shadow Boards

Brady proposed to increase the visibility of Lockout/Tagout with custom shadow boards. After a successful test phase with a single board, Brady designed and helped implement 34 large, highly visible Lockout/Tagout shadow boards.

The fully customisable shadow boards were equipped with Lockout/Tagout tool shadows and attachment systems for our customer’s complete inventory. Filled to the brim with reliable safety solutions, the large and highly visible shadow boards were then implemented in relevant workplace locations, where they act as a beacon that continuously signals the importance of workplace safety.

In addition, the custom Lockout/Tagout shadow boards help drive the efficient use and availability of Lockout/Tagout tools in the workplace. Tool shadows show at a glance where and how many Lockout/Tagout tools are available, and where they need to be returned when maintenance is done. The shadow boards also offer space to attach work permits that clearly communicate which Lockout/Tagout tools are required to work safely.

Results: Highly Visible, Efficient Lockout/Tagout Tool Distribution

With 34 highly visible custom shadow boards implemented, strong, visual and constant reminders help keep 'working safely' top of mind in our customer’s workplace. In addition, the Lockout/Tagout shadow boards help drive the efficient use of the soy processor’s existing Lockout/Tagout programme.